Textile Standards

Certificates are important, but …

OEKO-TEX®

We care as much as you do that our products do not contain human toxicological risks and harmful substances. How we ensure maximum consumer safety? By deciding many years ago that all our products should have STANDARD 100 by OEKO-TEX® – at Weitblick this is the mandatory minimum requirement in product development.

STANDARD 100 is a seal of quality awarded by independent testing institutes in several countries and covers testing for harmful substances on the finished product. So if a high level of product safety is important to you, with test criteria that go far beyond national and international legal requirements, then this seal also exceeds your demands.

We want all our manufacturing steps to always be compatible with the health protection and production conditions of local workers. In this context, environmentally friendly production processes are to be implemented on a permanent basis, natural resources are to be used efficiently, and environmental pollution is to be reduced. All this is ensured by the STeP certificate.

Within the framework of the STeP certificate, not only individual sustainability aspects are checked, but the production conditions are analysed and evaluated holistically. STeP analyses all key areas of the company within the framework of six modules:

- Chemicals management

- Environmental performance

- Environmental management

- Social responsibility

- Quality management

- Health & Safety

Want an inside look at our supply chain?

You shall have it!

We could tell you a lot about our production conditions. Just convince yourself! This is possible with the traceable product label MADE IN GREEN by OEKO-TEX®! In addition to fair and ecologically sustainable manufacturing conditions, it also ensures that the material used is free of harmful substances. It is visible to you through the clear labelling of all certified products and the associated traceability of the supply chain of a specific item. This is your direct insight into our textile supply chain. You can see exactly which production stage your product has passed through in which part of the world. Each product is equipped with an individual label on which you will find a product ID. You can enter this at www.oeko-tex.com/de/label-check.

Two labels create a third: ‘MADE IN GREEN’

THE GREEN BUTTON

We certify a wide range of our products with the Green Button. It is a meta-seal that on the one hand requires other certificates and on the other hand demands that 26 minimum social and ecological standards are met. In addition, we as a company have to prove our due diligence obligations in another 20 criteria. The Green Button thus recognizes textiles that are produced under particularly high social and environmental standards and whose supply chain is extremely sustainable.

The certification process involves a lot of effort, but we are happy to face it. Because the seal fits in perfectly with our philosophy – and you get even more assurance that you are holding workwear in your hands that has been produced in a holistically fair and ecological manner. At the same time, the Green Button gives you clarity and helps you to make your consumption as sustainable as you would like it to be.

SOCIALLY SOUND | Good for people

The Green Button sets mandatory requirements for decent work, from guaranteed minimum wages and compliance with working hours to a ban on child labour and forced labour.

ENVIRONMENTALLY SOUND | Good for nature

The Green Button bans the use of hazardous chemicals and softeners and lays down mandatory limits on effluent discharge.

GOVERNMENT-RUN | A label you can trust

The government lays down the criteria and conditions for the Green Button – guaranteeing clarity you can trust.

INDEPENDENTLY CERTIFIED | Independent audits

Independent auditors review compliance with the criteria set.

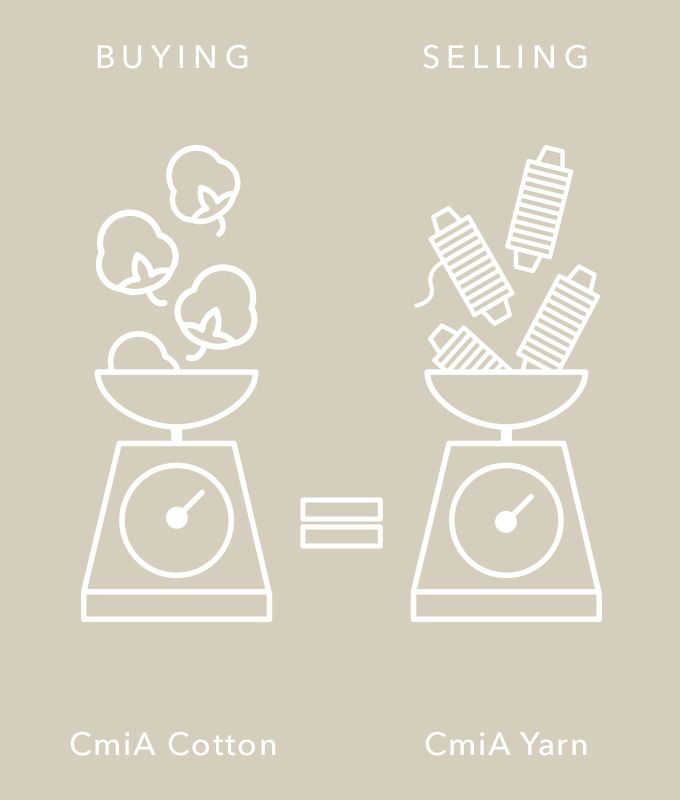

Cotton made in Africa

We encourage the ‘Mass Balance Supporter’ model

Because farmers can sell larger quantities of their cotton through the Fairtrade cotton commodity model, it opens up both fair trading conditions and new paths for social change and greater environmental protection. Learn more at www.info.fairtrade.net/sourcing

FLO ID: 41220 or WEITBLICK

Supporting Fairtrade Cotton

Stable minimum prices, even when market prices are low